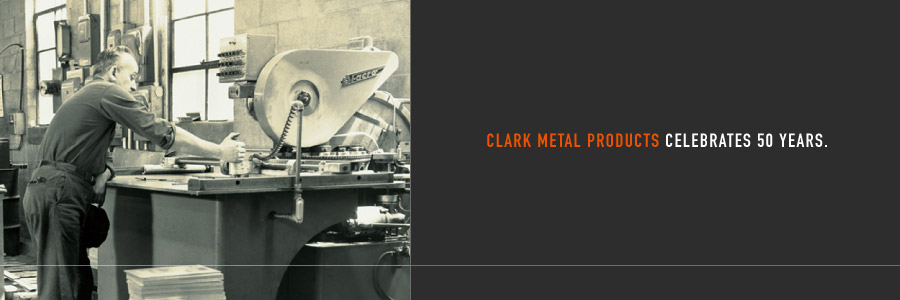

Clark Metal Products Celebrates 50 Years.

Beginnings

Clark Metals was born out of adversity, and for a while, adversity was all it knew. J.W. Clark was neither a born entrepreneur, nor someone particularly suited to the role by temperament. He was a financial man, known to be careful with numbers and money, somewhat reticent around anything so unpredictable as people.

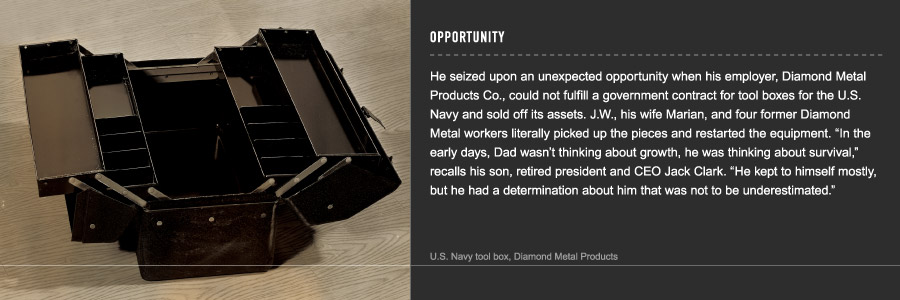

Opportunity

He seized upon an unexpected opportunity when his employer, Diamond Metal Products Co., could not fulfill a government contract for tool boxes for the U.S. Navy and sold off its assets. J.W., his wife Marian, and four former Diamond Metal workers literally picked up the pieces and restarted the equipment. “In the early days, Dad wasn't thinking about growth, he was thinking about survival,” recalls his son, retired president and CEO Jack Clark. “He kept to himself mostly, but he had a determination about him that was not to be underestimated.”

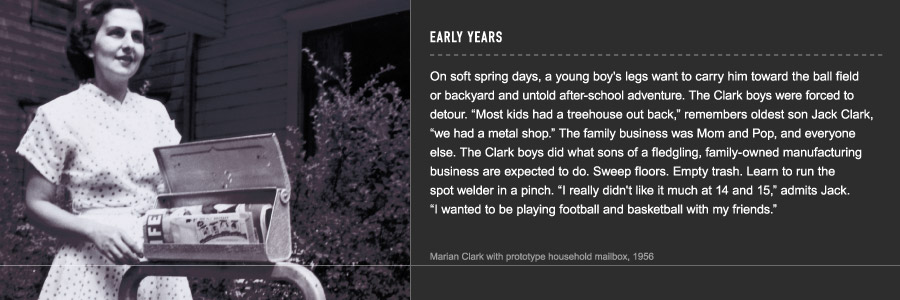

Early years

On soft spring days, a young boy's legs want to carry him toward the ball field or backyard and untold after-school adventure. The Clark boys were forced to detour. “Most kids had a treehouse out back,” remembers oldest son Jack Clark, “we had a metal shop.” The family business was Mom and Pop, and everyone else. The Clark boys did what sons of a fledgling, family-owned manufacturing business are expected to do. Sweep floors. Empty trash. Learn to run the spot welder in a pinch. “I really didn't like it much at 14 and 15,” admits Jack. “I wanted to be playing football and basketball with my friends.”

Steady growth

Time passed. Dad won enough orders to meet payroll. Mom (Marian Clark) made lunch for visiting clients and served it on the everyday plates – the only plates – at the kitchen table. Quietly, steadily, two boys and a business grew strong in Blairsville.

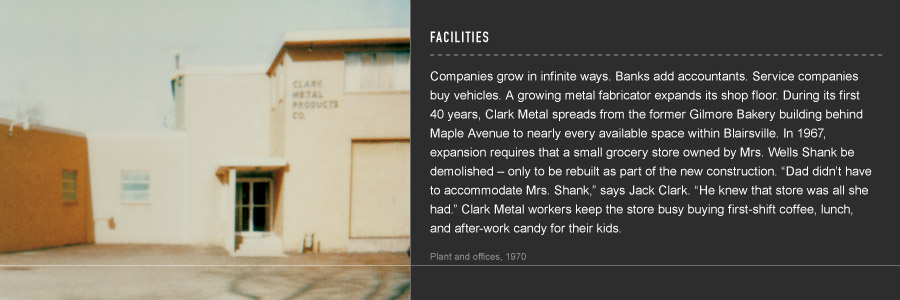

Facilities

Companies grow in infinite ways. Banks add accountants. Service companies buy vehicles. A growing metal fabricator expands its shop floor. During its first 40 years, Clark Metal spreads from the former Gilmore Bakery building behind Maple Avenue to nearly every available space within Blairsville. In 1967, expansion requires that a small grocery store owned by Mrs. Wells Shank be demolished – only to be rebuilt as part of the new construction. “Dad didn't have to accommodate Mrs. Shank,” says Jack Clark. “He knew that store was all she had.” Clark Metal workers keep the store busy buying first-shift coffee, lunch, and after-work candy for their kids.

Expansion

By 1993, Clark outgrows its boundaries and acquires the Metals Conversion plant in the Serell Industrial Park where it consolidates all office, manufacturing, and finishing and screen-printing operations. The owners can no longer shout through the screen door to someone at the plant. Says Jack Clark, "For the longest time, I must have held a record of sorts for the shortest commute to work."

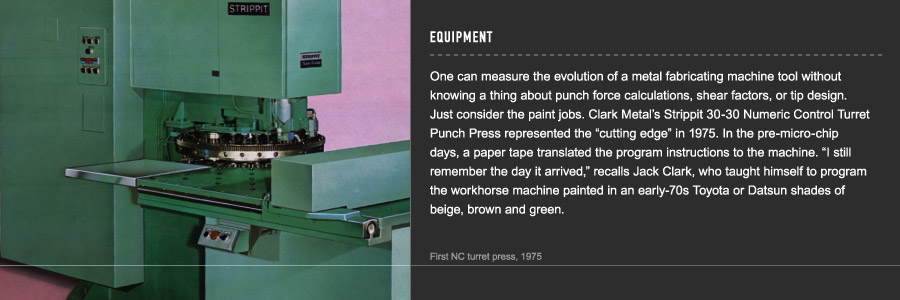

Equipment

One can measure the evolution of a metal fabricating machine tool without knowing a thing about punch force calculations, shear factors, or tip design. Just consider the paint jobs. Clark Metal's Strippit 30-30 Numeric Control Turret Punch Press represented the "cutting edge" in 1975. In the pre-micro-chip days, a paper tape translated the program instructions to the machine. "I still remember the day it arrived," recalls Jack Clark, who taught himself to program the workhorse machine painted in an early-70s Toyota or Datsun shades of beige, brown and green.

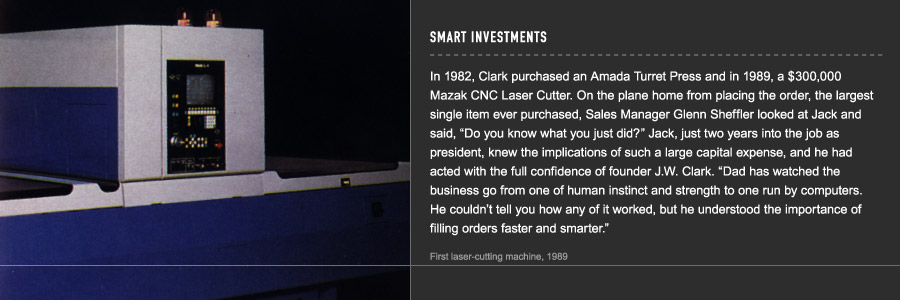

Smart investments

In 1982, Clark purchased an Amada Turret Press and in 1989, a $300,000 Mazak CNC Laser Cutter. On the plane home from placing the order, the largest single item ever purchased, Sales Manager Glenn Sheffler looked at Jack and said, "Do you know what you just did?" Jack, just two years into the job as president, knew the implications of such a large capital expense, and he had acted with the full confidence of founder J.W. Clark. "Dad has watched the business go from one of human instinct and strength to one run by computers. He couldn't tell you how any of it worked, but he understood the importance of filling orders faster and smarter."

Family-owned

As the company's reputation for producing high-quality metal components grew, so did its reach into new markets. Sons Jack and Dave saw fierce competition in the 1980s, leaving them with the decision to grow or perish. They hired a manufacturer's rep from Cleveland to boost sales in nearby states. One small problem – Clark Metals had never produced a single piece of sales or product literature. "Dad never saw the need," says Jack. The sales reps convinced Jack to ghost-write a letter that they would send to J.W., making the case for printing a sales brochure. "Dad relented, but I think it was a sign to him that the business had changed."

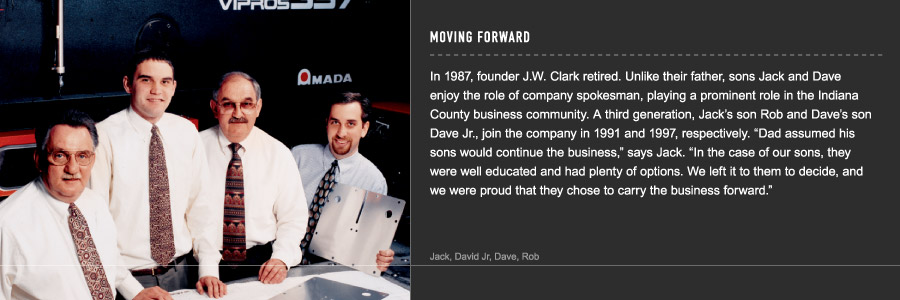

Moving Forward

In 1987, founder J.W. Clark retired. Unlike their father, sons Jack and Dave enjoy the role of company spokesman, playing a prominent role in the Indiana County business community. A third generation, Jack's son Rob and Dave's son Dave Jr., join the company in 1991 and 1997, respectively. "Dad assumed his sons would continue the business," says Jack. "In the case of our sons, they were well educated and had plenty of options. We left it to them to decide, and we were proud that they chose to carry the business forward."

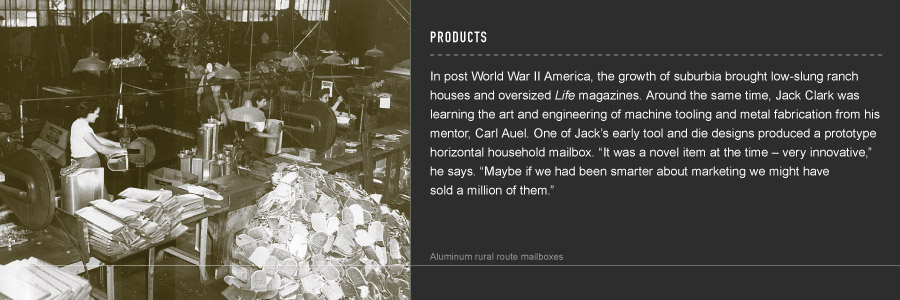

Products

In post World War II America, the growth of suburbia brought low-slung ranch houses and oversized Life magazines. Around the same time, Jack Clark was learning the art and engineering of machine tooling and metal fabrication from his mentor, Carl Auel. One of Jack's early tool and die designs produced a prototype horizontal household mailbox. "It was a novel item at the time – very innovative," he says. "Maybe if we had been smarter about marketing we might have sold a million of them."

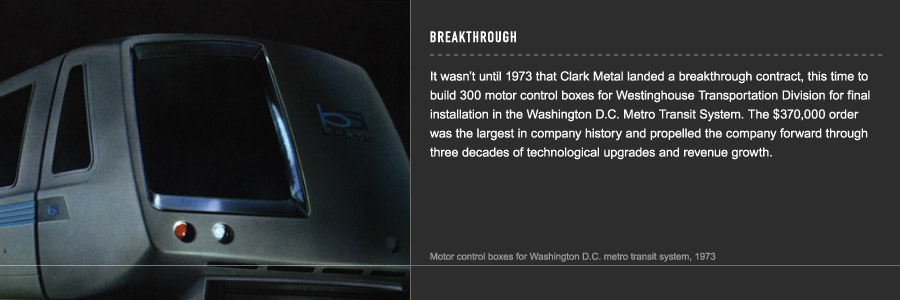

Breakthrough

It wasn't until 1973 that Clark Metal landed a breakthrough contract, this time to build 300 motor control boxes for Westinghouse Transportation Division for final installation in the Washington D.C. Metro Transit System. The $370,000 order was the largest in company history and propelled the company forward through three decades of technological upgrades and revenue growth.

Dedication

Clark Metal never hired a consultant to figure out how to relate to its employees. They relied instead on the golden rule of business. Treat people right, and they'll return the favor with a good day's work. Consider long-time Plant Manager, Ed Hendricks, who retired in 1993 after 28 years of loyal service. "You couldn't ask for a more dedicated employee or friend," says Jack Clark.

Commitment

There have been others who spent nearly all of their working lives with the company. "We've always been very open with the employees," says Jack, who started the practice of quarterly all-staff meetings that continues to this day. Orders up or orders down. New competition and familiar price pressures. Shop floor issues discussed and shop floor issues resolved. A family business made stronger by the contributions of hundreds of Indiana County families throughout the past 50 years.

Thank you

Clark Metal Products would like to thank the members of the Clark family, our employees (both past and present), our vendors, and our valued customers. We appreciate your support, your service, and your patronage — and we look forward to the next successful 50 years.